Warehouse Racking Systems and Storage Solutions

Official DistributorWe design a wide range of racking systems that will provide optimal storage solutions according to the clients’ particular needs. Our core activity is the development and manufacturing of top-quality racking systems for the storage of a large diversity of goods. Our storage racks are fully compliant with latest regulations.

WE PROVIDE!

FREE PROJECT DESIGN

of racking systems according to your particular needs

- • Conventional Selective Pallet Racks

- • Drive-In Pallet Racks

- • Cantilever Racks

- • Mezzanine Racks

- • Wide Span Shelving

Conventional Selective Pallet Racks

WE PROVIDE!

FREE PROJECT DESIGN

of racking systems according to your particular needs

Conventional Pallet Racks can be easily adapted to most of the warehouses due to a wide range of available widths, lengths and heights. The wide range of available accessories makes the Racking System fully customizable. Pallet Racks are suitable for any types of pallets.

Conventional Pallet Racks are the most popular, functional racking system in the industry. As the best solution for warehouse systems with palletized products, they allow the storage of a wide variety of goods.

Conventional Selective Pallet Racks offer the following advantages:

- • Ability to store multiple references;

- • Maximum design flexibility;

- • Direct and selective access to all pallets;

- • Easy control of stocks;

- • Maximum adaptability to any load type both in terms of weight;

- • Suitable for any handling equipment;

- • Simple and reliable system;

Dimensions:

- • Frame Widths: 1050mm;

- • Beam Length: 1850mm / 2700mm / 2200mm / 3300mm;

- • Height: 1500mm – 12000mm;

Load Capacities:

- • Load Capacity on 2 Beams: from 500 kg up to 4800 kg

- • Load per Bay: from 5 000 kg up to 22000 kg

Drive-In Pallet Racks

WE PROVIDE!

FREE PROJECT DESIGN

of racking systems according to your particular needs

Drive-in racking considerably increases the storage capacity of the warehouse. The drive-in systems make the perfect choice for large stocks of similar product types. Drive-In Pallet Racks are high density storage systems that reduce overall space requirements by at least 35%, compared to a conventional pallet racks. Drive-In Racks are a perfect solution for cold storage warehouses.

Storage of pallets with fragile goods that cannot be stacked on top of each other might also benefit from using the Drive-In racking systems. The 140 mm cross section upright frames allow us to develop racking systems with considerable heights.

Types of Drive-In racking systems:

According to the clients’ requests the following systems could be developed:

- • Conventional Drive-In systems;

- • Drive – through systems;

Conventional Drive-In racks apply the LIFO (last in, first out) principle for loading and unloading. Drive-through installations are loaded and unloaded according the FIFO (first in, first out) principle. To guide the truck or pallets and to protect the installation we recommend the use of ground rails.

Drive-in pallet racks and drive-thru racks are rolled-formed. Products are stacked several pallets deep, and handling equipments are entering the Drive-In rack structure to store or collect pallets.

Load Capacities:

- • Load Capacity per level: up to 9,000 kg

- • Load per Bay: up to 36,000 kg

Cantilever Racks

WE PROVIDE!

FREE PROJECT DESIGN

of racking systems according to your particular needs

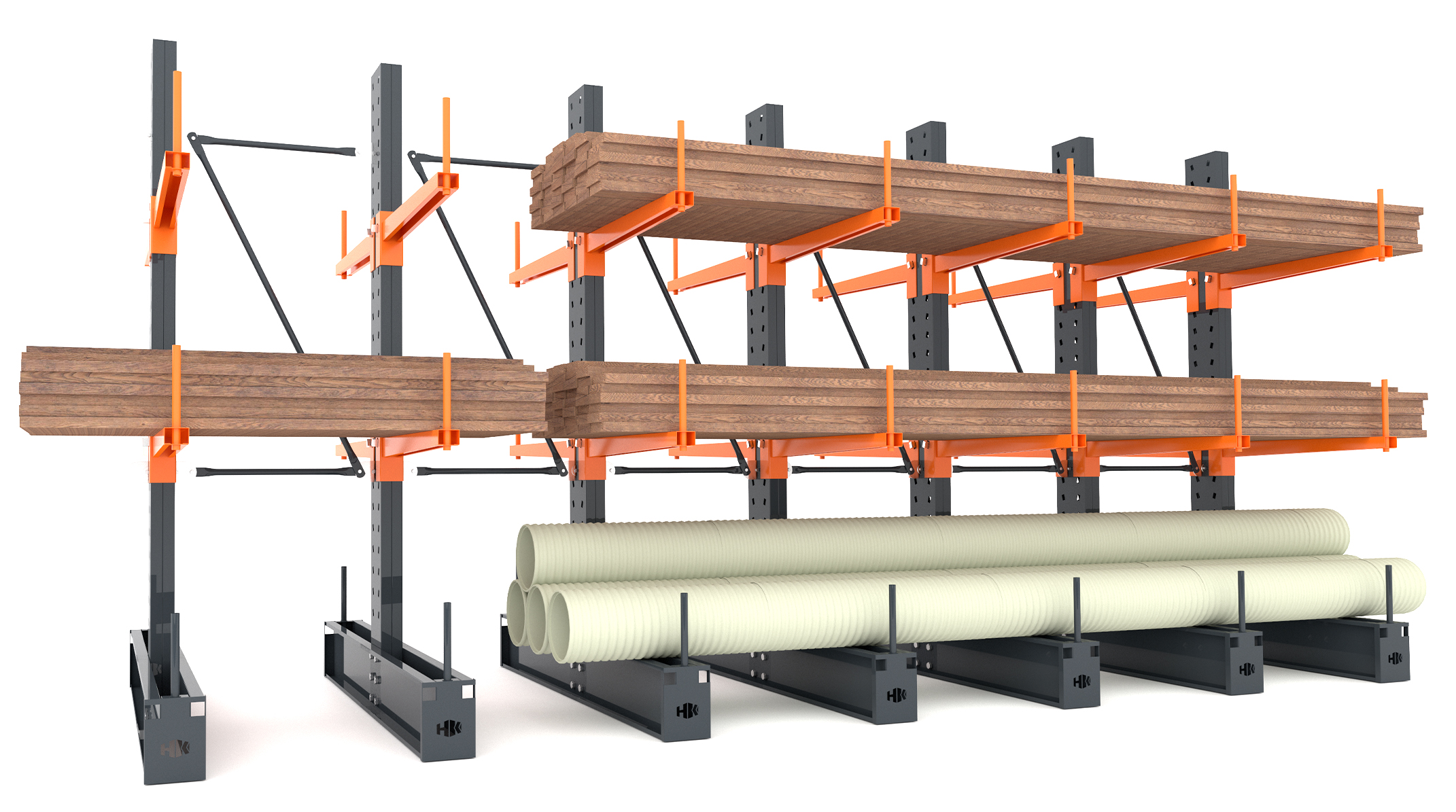

Cantilever racking is a system designed for the storage of various wide span loads. It can be flexibly adapted for different weights and measures. This storage system is intended for loads such as wooden boards, metal profiles, pipes and tubes etc.

We can supply Cantilever Racks for heavy and medium duty storage.

The Cantilever Racking systems are multilevel storage racks designed and engineered to offer enhanced strength and safety. All components are powder coated with a durable paint and are scratch-resistant. The modern design of the Cantilever Racks will to maximize your storage space while giving easy access to the products.

Applications:

- • Suitable for various wide span loads storage such as wooden boards, metal profiles, pipes and tubes etc;

- • Cantilever Racking systems are commonly used in DIY shops, Hardware Stores or Production Warehouses;

- • With Cantilever racking you can work by the safest storage practices. The cantilever can be used indoors or outdoors;

- • Cantilever Racks could be single sided or double sided. The use of Cantilever Racks will optimize the storage space within your warehouse;

Load Capacities:

- • Load Capacity per level: up to 5,000 kg

- • Load per Bay: up to 30,000 kg

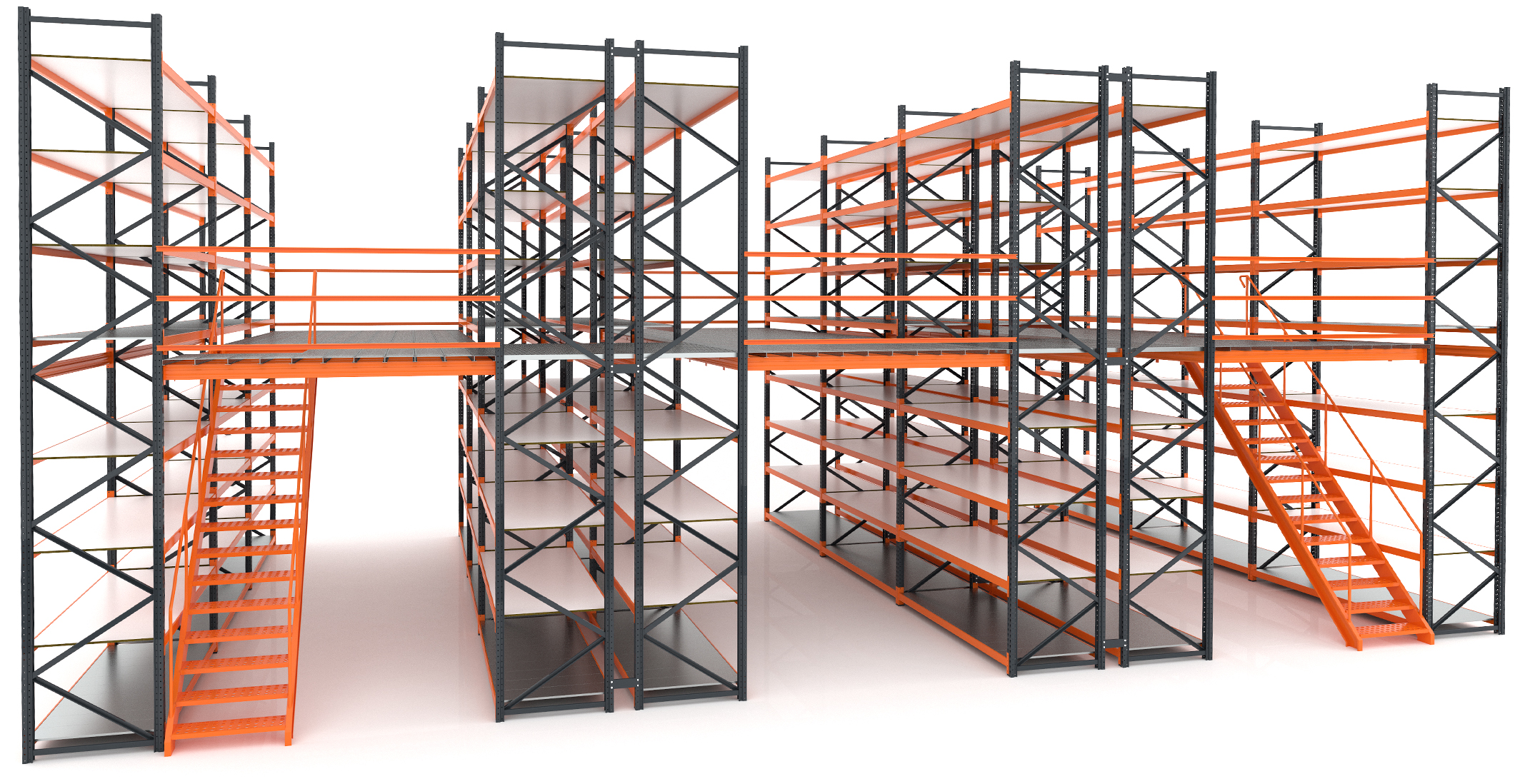

Mezzanine Racking Systems

WE PROVIDE!

FREE PROJECT DESIGN

of racking systems according to your particular needs

Mezzanines systems are the type of racks made from steel structures that provide new elevated surfaces on warehouse or premises floors, creating additional space for storage, work areas, offices, etc. in an efficient and economical way.

Benefits of Mezzanine Racks

Installation of Mezzanine Racks is fast and easy. Mezzanine Racking system are compatible with other of shelving or industrial storage systems. The Mezzanine Floors could be built on Conventional Pallet Racking systems or shelving racks or any other metal racks.

Long Span Shelving

WE PROVIDE!

FREE PROJECT DESIGN

of racking systems according to your particular needs

This type of racks is used for goods of medium weights that are commonly stored manually. The long span racks are medium duty shelves that are fully adjustable and are designed for storage of small loads. These metal racks prove useful in almost any situation: shelf racking, long span racking, multi-tier and high-rise constructions and could also be combined with mezzanine floors.

Long Span Shelving is the perfect industrial shelving solution, which can satisfy most of the storages according to the clients’ needs and loading requirements. In addition, longspan shelving has a great modular design and is easy to assemble thus saves your space and time.

Longspan is equally suited for warehouse and office environments. The frames and beams can be powder-coated in any RAL color for enhanced aesthetics.

Longspan features:

- • Load Capacities: Up to 1000 kg / level

- • Available Decking: chipboard, metal or mesh shelves

- • Quick assembly; Good stability; Low cost;

- • Quick assembly; Good stability; Low cost;